Mark Koenig

Hand pads permit cost effective manual cleaning

June 26, 2018 - POLINOX® hand pads from PFERD are a versatile and cost- effective answer to a wide range of grinding and cleaning needs. Suitable for very fine grinding on small to large surfaces and contours, and for manually cleaning metal and painted surfaces, they are highly flexible, enabling optimal adjustment to the contour of the workpiece. This allows users to access hard-to-reach areas.

The pads can achieve matte and satin-finished surfaces and can be used for wet or dry grinding. Well suited for light deburring work, corrosion removal, cleaning jobs in tool and mold-making, and fine grinding/patterning of stainless steel. Made from non-woven material with a highly open structure impregnated with either aluminum oxide A or silicon carbide SiC grain, PFERD hand pads, which can be supplied in bulk quantities, follow industry-standard color coding for easy selection.

Maroon-colored general-purpose pads are the most widely used of all hand pads. Their aluminum oxide grain is noted for its toughness and durability on tasks such as cleaning, deburring, rust removal, blending and finishing.

Green-colored pads are general purpose grade pads made with aluminum oxide. Commonly, though not exclusively, used in the food service industry, these pads are recommended for light duty and finishing applications.

Tan-colored heavy-duty pads consist of a dense aluminum oxide grain concentration on heavy backing material. Designed for the most severe applications, they are extremely durable and resist tearing and fraying. Excellent for removal of oxidation, weld cleaning, deburring, and finishing stainless steel and aluminum.

The white-colored hand pad contains no abrasive. It is used primarily for applying lubricants, detergents, polishes, etc. to almost any material. Commonly used for cleaning plastics, glass, ceramics, porcelain, chrome, copper and stainless steel.

And finally, the gray-colored pad is an ultra-fine silicon carbide pad that provides a precise, fine cutting action. Well suited for light cleaning and fine finishing on a variety of material including metal, plastic, glass and wood.

PFERD Inc.

Milwaukee

Cutting lube increases tool life

June 22, 2018 - Hougen Manufacturing Inc., Swartz Creek, Michigan, manufacturer of magnetic drills and annular cutters announces their new RotaGel™ Cutting Lube. In most metalworking applications, nothing is more important than proper tool lubrication. RotaGel Cutting Lube is an is an industrial lubricant that provides superior protection to the cutting tool even in hard, high torque machining applications.

RotaGel Cutting Lube is a very environmentally safe lubricate because its core ingredients are based off of a food grade lubricant. It is non-toxic and biodegradable.

With the consistency of a creamy gel, RotaGel has properties that help it adhere to the tool and reduce friction throughout the cut. Because it is formulated with a Hougen blue color, it allows the operator to consistently gauge where the lubricant is applied and visually assures thorough coverage. Designed for use on all metals including: carbon steel, stainless steel, inconel, hastalloy, titanium, aluminum and other alloys and exotics. RotaGel is a versatile cutting lubricant that provides maximum lubrication and increased tool life with many different applications and tools. Example of applications include: annular cutters, taps, drills, saws, reamers, endmills, general lubrication and more. Not only does RotaGel provide lubrication to cutting tools, it also improves hole and surface finishes.

RotaGel is available in single net weight 8 oz. (227g) tubes (Part No. 11748) or in a case of ten tubes (Part No. 11748-10). The product is made in the USA.

Detergents formulated to be environmentally friendly

June 14, 2018 - Maximize the performance of your part washing system with Renegade solvent-free detergents for automatic and manual parts washers. Formulated to be environmentally safe and health risk free, Renegade detergents remove grease, soil, paint, corrosion, oil, and other contamination from the surfaces of different types of parts.

RENEGADE JET WASH DETERGENT FOR AUTOMATIC PARTS WASHERS

Renegade Jet Wash Detergent is compatible with spray cabinet automatic parts washers. Includes rust inhibitor, and is low foaming and low residue.

Renegade Jet Wash Detergent Liquid Sizes: 1 Gallon Concentrate; 5 Gallon; 55 Gallon Concentrate

Renegade Jet Wash Detergent Powder Sizes: 40 Lb. Pail; 450 Lb. Drum

RENEGADE PARTS WASH DETERGENT FOR MANUAL PARTS WASHERS

Renegade Parts Wash Detergent for Manual Parts Washers is solvent-free, fast drying, low foam, low residue, cuts grease and suspend oils quickly. Includes skin conditioner and rust inhibitor. Environmentally friendly, bio-degradable formula contains no Phosphates CFC’s, ODC’s, silicates, borates, halogens, phenols or chelating agents.

Renegade Manual Parts Wash Detergent Sizes: 5 Gallon Concentrate; 3/4 Gallon Super Concentrate; 55 Gallon Concentrate

Renegade Parts Washers and Detergents line also includes additives, rust inhibitors, degreasers, and defoamers.

Renegade Parts Washers and Detergents

Reedsburg, Wisconsin

800/774-7900

www.renegadepartswashers.com

Abrasive discs transform grinding operations

June 13, 2018 - Walter Surface Technologies, Windsor, Connecticut, has unveiled its new ErgoFlex™ abrasive disc—a safer, more ergonomic, equally powerful alternative to traditional grinding wheels.

Combining a type 29 disc design and Walter’s proprietary Cyclone™ technology, ErgoFlex™ is designed for extremely smooth weld blending on both flat and curved surfaces. It allows for a more comfortable working angle than type 27 depressed center grinding wheels, along with cleaner, quieter grinding operations. With an aggressive 36 grit or higher abrasive grain blend, ErgoFlex™ removes material fast with minimal gouging risk.

“For manufacturing professionals looking to balance safety, ergonomics, and productivity, ErgoFlex™ is the perfect solution,” says Marc Brunet-Gagné, Product Manager of Bonded Abrasives at Walter Surface Technologies. “ErgoFlex™ offers the same power and speed as traditional grinding wheels, but with 95% less dust, 50% less noise, 50% less vibrations, and better ergonomics. It’s also less likely to gouge materials, thus increasing efficiency and cost savings."

Designed for heavy manufacturing, pipeline construction, metal fabrication, and other industrial needs, ErgoFlex™ is suitable for use in a wide range of grinding operations including grinding welded steel and stainless steel, heavy grinding, weld removal, and beveling.

Walter Surface Technologies

Windsor, Connecticut

860/298-1100

www.walter.com

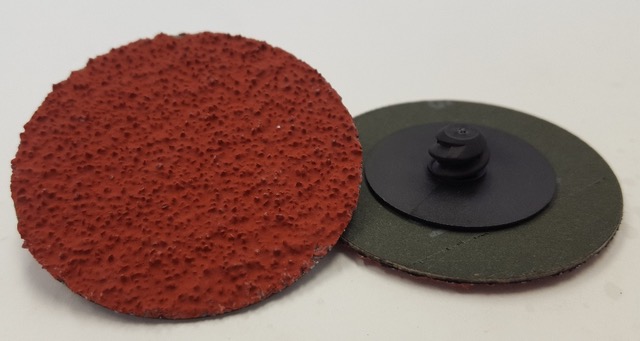

Discs feature a high concentration of ceramic grain

June 7, 2018 - Mercer Industries recently released its next generation of premium ceramic products with the introduction of Ceraflame 2™ Resin Fibre Discs. These discs feature a high concentration of ceramic grain lasting 40% longer than the original grain. Ceramic, a premium man-made grain that self-sharpens throughout its life, is the longest lasting, coolest cutting abrasive in the Mercer Industries line.

These new resin fibre discs are specially formulated to be used on high performance alloys, high carbon steel, stainless steel, non-ferrous metals and heat sensitive metals. They have a heavy-duty vulcanized fibre backing and a top size coating for cool, fast cutting. Available in grits from 24 to 80, they can be used to strip, grind, debur and polish. The discs are contaminant free to prevent stainless steel from rusting and will not stain or burn material.

Ceraflame 2™ Premium Ceramic Resin Fibre Discs are available in 4 ½ in. by 7/8 in. hole with a max RPM of 13,300.

“We are excited to be able to offer Ceraflame 2™ to the marketplace,” states Gayla Brainerd, Director of Sales. “We work closely with our customers to develop products that fill requirements that are not necessarily being met by the current products on the market. This is a natural progression of the Ceraflame™ product line, providing our partners with a premium offering to help satisfy their customer’s needs.”

Mercer Industries

Ronkonkoma, New York

800-221-5202

www.mercerindustries.com

Self-clinching threaded standoffs offer reliable fastener solutions

June 4, 2018 - PEM® TSO4™self-clinching threaded standoffs from PennEngineering offer reliable fastener solutions to securely stack or space components in ultra-thin stainless steel assemblies. These hardened stainless steel fasteners clinch into stainless sheets as thin as .025 in. / 0.63mm and become permanent parts of an assembly. The standoffs ultimately will reduce the amount of required hardware in an assembly, promote thinner and lighter designs, and minimize typical handling issues associated with loose hardware.

Among unique design features, the fastener’s thread design at the barrel end minimizes the length for a mating screw. Shorter standoffs are typically thru-threaded and longer standoffs are blind. Thread-type variations with a thicker wall can further be specified to provide increased bearing surface for the mating component or panel. For applications in potentially corrosive environments, an optional nickel plating can be added for excellent corrosion resistance.

PEM TSO4 standoffs are available in thru-threaded or blind threaded versions and in a variety of lengths and several standard thread sizes (#2-56, #4-40, and #6-32 / M2.5, M3, and M3.5). They are manufactured from hardened 400 Series stainless steel for use in stainless sheets with maximum hardness up to HRB 88 on the Rockwell “B” scale or HB 183 on the Brinell scale.

The standoffs mount simply and quickly by pressing the fastener into a round hole in the host sheet and applying sufficient squeezing force using a standard press to embed the standoff’s head flush in the sheet and complete the process. A single mating screw completes the attachment process.

PennEngineering

Danboro, Pennsylvania

800/237-4736

www.pemnet.com

Stretch-Back FR Cotton Welding Jacket

May 21, 2018 - Staying cool, comfortable, and protected while welding is now easier with the new Stretch-Back FR Cotton Welding Jacket (JF1625-NG) from Black Stallion.

The lightweight stretch-back welding jacket offers all the protection of a Black Stallion standard welding jacket, with the added comfort of a flame-resistant cotton stretch knit back panel.

The looped knit yarns of the back panel are extremely flexible, offering comfortable stretch. This horizontal stretch provides just the right amount of “give” as a welder moves his shoulders and arms. These looped knit yarns also allow more air to flow through the fabric. This increased airflow provides more breathable comfort and can create a cooling effect as the job heats up.

And, the seven ounce cotton stretch knit back panel includes ASTM F1506 compliant flame resistance. Welders get the added benefit of comfort and breathability without sacrificing protection.

The front, shoulders, arms, and neck of the JF1625-NG are constructed of nine ounce flame-resistant cotton. The jacket offers protection for most light welding applications and includes all the high-quality, innovative features you expect from Black Stallion. The stand-up welder’s collar, with snap closure, helps keep sparks off the neck. And, the extended 32” length offers enhanced torso protection.

Six powder-coated stainless steel front snaps secure the jacket with less gapping. Other welding jackets use as little as four buttons, leaving wide gaps for sparks to potentially penetrate. The six front snaps are reinforced with leather backing to reduce the risk of tearing.

The new Stretch-Back FR Cotton Welding Jacket (JF1625-NG) from Black Stallion is available through independent welding and safety distributors nationwide.

Black Stallion

Santa Fe Springs, California

800/527-3826

www.blackstallion.com

Ceramic Ultra-X discs

May 15, 2018 - The new Ceramic Ultra-X grain is manufactured in a new way that results in a much finer crystalline structure. Such a unique mineral fracture provides the abrasive product with a longer life, and more aggressive grains with an improved self-sharpening effect.

Significant performance advantages include a higher metal removal rate at faster cutting speeds with a lower grinding temperature and less friction. All of which correlate to shorter cycle times and less disc changes, resulting in reduced cost per part and an excellent cost/performance ratio.

In addition, the Ceramic Ultra-X line is top-sized. A top-sized product can positively impact the workpiece through a reduction in metal discoloration/oxidation, as well as minimal heat related stress cracks. It can also benefit the abrasive through reduced loading, glazing and dulling.

Gemtex Abrasives

Toronto, Canada

800/387-5100

www.gemtexabrasives.com

Pins are ideal alternatives to screws

May 9, 2018 - New stainless steel PEM® TK™TackSert® pins from PennEngineering introduce ideal alternatives to screws for attaching thin panels in assemblies. They can securely attach panels of any material to base panels manufactured from common casting materials (such as AZ91D) or plastics (such as ABS and printed circuit boards). Unique design features promote reliable performance in service.

PEM TK TackSert pins deliver multiple advantages over screws by eliminating any need for mating threads from tapped holes or inserts and the rework frequently required due to screw cross-threading and driver bit “cam-out.” Patches intended to prevent fastener loosening in service are unnecessary.

Among pin design features, a tapered tip assists in pin location to enable easier alignment into a base panel, a specially engineered diagonal broaching knurl (instead of threads) creates a firm interference fit without hole-tolerance issues, and a low-profile head minimizes protrusion on the attached panel.

The pins are offered in a variety of lengths and can successfully attach sheets with thicknesses from .067 in. / 1.7mm to .185 in. / 4.7mm, depending on pin length.

PennEngineering

Danboro, Pennsylvania

800/237-4736

www.pemnet.com

8.0 Ah and 4.0 Ah slim pack battery systems

My 1, 2018 - Metabo Corp., international manufacturer of professional grade cordless and corded hand-held power tools and accessories, is pleased to introduce its 8.0 Amp hour (Ah) and 4.0 Ah slim battery pack with Lithium High-Density (LiHD) Battery Technology.

"The market introduction of our LiHD battery pack technology was a major breakthrough in 2015; with our latest battery packs we went a step further," said Horst W. Garbrecht, Metabo Germany’s CEO. "We wanted to show professional users that they can depend on Metabo for a system that has influenced the development of battery pack technology from the beginning and continues to do so.”

In 2013, Metabo revolutionized the industry with the World’s First 18V 4.0 Ah full size battery pack. This year in May, Metabo is doing it again with the World’s First compact 4.0 Ah. The newly designed battery packs, built on Metabo’s Ultra-M Technology have significantly more performance and capacity compared to the previous generation – at the same size. The 8.0 Ah battery is even better suited for cordless tools with higher power requirements, like small angle grinders, saws, large rotary hammers and the 9 in. large angle grinder. And the 4.0 Ah compact battery pack is the same size as our initial LiHD 3.1 Ah compact (introduced in 2015) with a compact and lightweight design, perfect for drilling or screw driving applications. The 4.0 Ah slim battery pack is about 2 ¼ pounds less than a double row, full size 4.0 Ah Li-ion battery pack, increasing ease of use and decreasing worker fatigue.

In order to deliver increased runtime and power, Metabo is excited to be the first on the market to introduce the newest 21.700 cells. They are slightly larger than the previous generation of LiHD cells, yet the battery pack size remains the same. This allows for even larger cell capacity while delivering higher currents to the tool, thus allowing true industrial grade performance.

New features of these battery packs include: improved positioning of the fuel gauge, now located at the front, for better visibility. The battery packs have a rubber bottom to help prevent sliding on surfaces while protecting work surfaces and the case against shocks. The battery’s upgraded seals help protect the batteries from metal and wood dust, increasing the batteries life. As always, Metabo batteries are fully compatible with all of Metabo’s past, present and future 18V Ultra-M systems.

The Ultra-M technology was designed specifically for industrial users, whose applications typically demand more power and longer run times. The key behind the system is a microchip in the battery that effectively communicates with the tool and battery charger. This ongoing communication ensures that each battery cell is evenly charged and discharged every single time, thus greatly extending the life of the battery as well as protecting the tools being used. Productivity is also greatly increased as a hot “spent” battery can be placed in the charger immediately after disconnecting from the tool. The charger’s built-in fan system quickly cools the battery pack as it begins the charging cycle, thus reducing overall charging time. The result is a battery that will effectively survive more charge/discharge cycles than other battery systems. Metabo offers an unconditional 3-year guarantee on their battery and charging system. The warranty applies regardless the number of charging cycles.

To fully utilize the power of this new longer running battery, Metabo features the industry’s largest range of cordless specialty metal tools in the industry. This includes many unique tools such as several problem-solving grinders, the industry’s only automatic tapping tool, a metal high speed drill as well as a complete line of fabrication and finishing tools.