July/August 2018 - OEMs that outsource metal parts to contract manufacturers must often guess at the production requirements for new products, so initial forecasts are often conservative or unrealistically high.

Because of this uncertainty, OEMs may be hesitant to invest tens of thousands of dollars in hard tooling. Instead, they choose to implement less expensive soft tooling options—even if that method increases the initial price per part.

As demand increases, however, OEMs ideally should transition to hard tooling, hybrid approaches and even progressive dies that speed turnaround time and drive down the price.

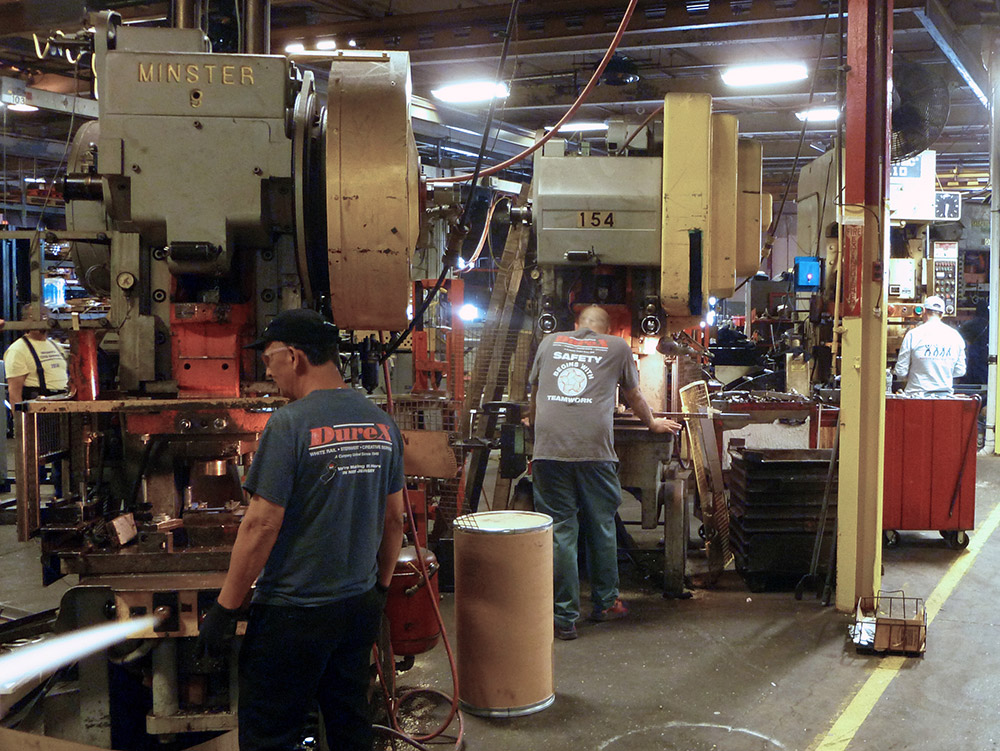

“As production requirements increase, transitioning to a more efficient type of tooling can save some OEMs tens of thousands of dollars a year with an ROI measured in weeks or a few months,” says Bob Denholtz, president of DureX Inc., a contract metal fabricator in Union, New Jersey. “Any good metal parts supplier should be able to help the OEM determine the most cost-effective tooling for their situation.”

Although tool selection involves various factors, including part size, metal thickness, complexity and finish, the cost per part is often related to the type of tooling used, says Denholtz.

Soft tooling

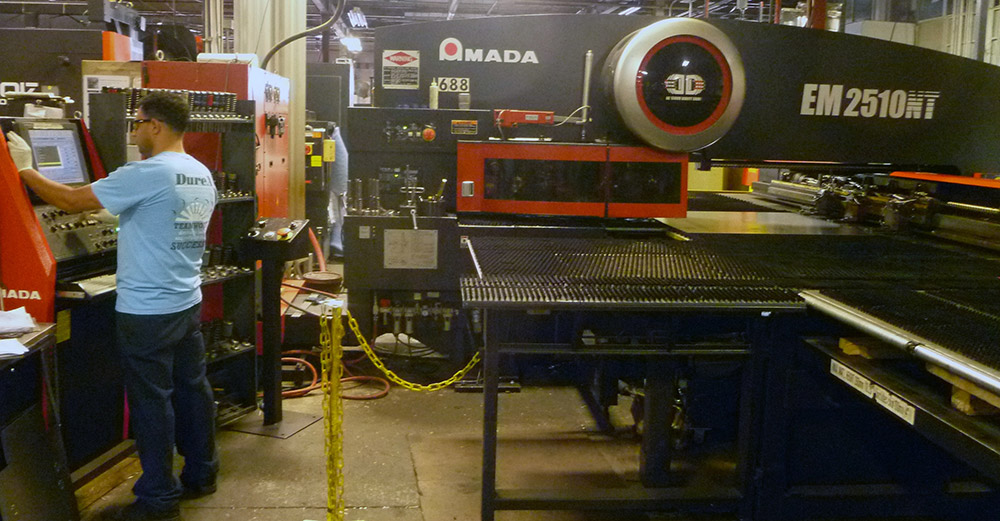

Low-volume part manufacturing often involves soft tooling for sheet metal fabrication. Usually this entails having a flat part or a slightly formed part getting holes, slots or tabs punched in it by a CNC laser or turret punch press before going to a press brake and getting bent to the proper angle.

“Soft tooling typically costs $75 to $500 but can cost up to $2,000 to $3,000 for more complex parts,” says Denholtz. “This can work for prototyping and low-volume production orders. However, it can take several minutes of machine time to make each part, depending on its complexity, so the cost per part is higher.”

One strategy to lower or even eliminate soft tooling cost is to borrow the tooling from a supplier’s “library of tools.” Because DureX has served a variety of markets for over 30 years, it has built up a substantial inventory of soft tools in many sizes and shapes. When appropriate, these tools can be put back in service.

“Suppliers with a wide range of experience have the most soft tools in their inventory so they may charge nothing or a discounted rate for a tool in their library,” says Denholtz. “Those contract parts manufacturers that only serve specific industries will generally have to charge customers for new soft tools.”

Hard tooling

When production volumes increase to 15,000 or more parts annually, OEMs often can reduce costs by moving from soft tooling to hard tooling. According to Denholtz, the cost of hard tooling can vary from $5,000 to $300,000 or more depending on size, complexity and whether it is designed to produce finished parts.

“When one OEM gave us a power supply chassis and cover to produce, they started at 500 parts per month with soft tooling,” says Denholtz. “However, when production requirements increased to 4,000 parts a month, we suggested they move to hard tooling to reduce the price from $22 to $15 a part. With a hard tooling cost of about $85,000, they achieved ROI in about four months.”

Unlike soft tools, hard tools are not available in a contract manufacturer’s “library.” They are built to produce that specific product, so each must be purchased. Still, there are ways to keep costs down, including using the same hard tooling for a family of products.

Hybrid tooling

As the name implies, hybrid tooling is a combination of soft and hard tooling. A part might begin as a flat piece of metal that is punched or formed with a soft tool and then it may undergo further forming by a hard tool.

For example, a ceiling fixture could start in a turret that punches all the holes and slots before it is moved to a hard die that forms up the sides into a box.

“So instead of putting a flat piece of metal in a brake and hitting it four times to bend the two sides and two ends, I could use a die and hit it once. So it only takes 30 seconds or less to make the entire part—instead of 2 minutes,” explains Denholtz.

Staged tooling

To create metal parts at even greater speed and volume as well as shrink the price per part further, staged tooling can be used. This basically involves moving a metal part between two high-performance dies, so the work is performed in two distinct processes that use hard tooling.

“Instead of taking 5 minutes in a machine to punch all the needed holes individually using a soft tool, I could make a blanking die and punch everything in one shot in 5 seconds,” says Denholtz. “Then I could put it in a box form and form it into shape in another 5 to 10 seconds.”

Progressive dies

The fastest, highest volume part production can be achieved by a progressive die, which accomplishes multiple operations in a single process using hard tooling. Depending on the part, a progressive die can often produce a finished part with every machine cycle.

“When an OEM asked us to produce a metal card cage to hold circuit boards, they were spending about $125 per cage,” says Denholtz. “When volume rose to 1,000 parts a week, we reduced the cost to $55 per cage by switching to a progressive die. Although the hard tooling cost was substantial—about $350,000—the OEM achieved ROI in only six weeks.”

Although working with a metal part manufacturer to select the best tooling option for the production volume is vital, partnering with a supplier that can also provide value-added finishing and assembly can further streamline the manufacturing process.

DureX Inc.

Union, New Jersey

908/688-0800