Above: Coolube lubricants are formulated from renewable plant-based oils.

MQL uses small amounts of lubricant applied directly to the workpiece

February 2019 - Minimum quantity lubrication (MQL) is a near-dry method of machining that minimizes the environmental impact of metal processing by significantly reducing fluid consumption and eliminating the need for coolant treatment and disposal. Other benefits include cleaner tools and extended tool life. However, MQL is a finely tuned lubrication method, and its two main considerations are fluid delivery and fluid quality. Considering which lubricant to use can make the difference between a so-so MQL experience and one that really knocks your socks off.

Two choices for MQL fluids

A good MQL fluid has very high lubricity and thermal ratings to withstand the high thermal and mechanical loads present during machine operation. There are generally two types of fluids used: synthetic ester oils and fatty alcohols formulated for the proper range of vaporizations and flash points.

Synthetic esters, such as Unist’s line of Coolube lubricants, are preferable for machining processes where the lubricating effect is of prime importance. This is the case for most materials and operations. These lubricants are designed for low viscosity while maintaining a high boiling and flash point, which gives better results under load and generates fewer vapors than conventional mineral oils.

Ester oils also have very good biodegradability and very low toxicity. Because such a small amount of the oil is applied, the parts are still considered dry (i.e., less than 2 percent of the lubricant is present on the chip). However, there will likely still be a very small amount of oil on the part directly around the cut. This minute amount of oil can help with corrosion resistance and item separation but may cause issues in some secondary operations.

Fatty alcohols offer less lubricity but, because of their lower flash point, provide more cooling. They are useful when extra cooling is needed more than lubricity, which is often the case on materials that have some natural lubricity. If a built-up edge is being formed on the tool when using a synthetic ester, the fatty alcohol may offer enough additional cooling to help minimize that buildup. Fatty alcohols have very good biodegradability and are toxicologically and environmentally harmless. Fatty alcohols also tend to be consumed more fully in the process, compared to synthetic esters, so the parts come out with little or no residue.

Wetting and emissions

The better the wetting properties, the better the lubricant will work. A fluid that spreads itself on the cutting surfaces is better at getting down into the interfaces between the tool and the workpiece. A quick way of comparing how fluids will wet atop a material is by taking a drop of liquid and putting it on the material and seeing how it spreads. The more widely it spreads, the better it is wetting.

Extreme pressure additives, such as sulfur, can greatly change the wetting property on different materials, so it is best to test with the specific fluid that will be used.

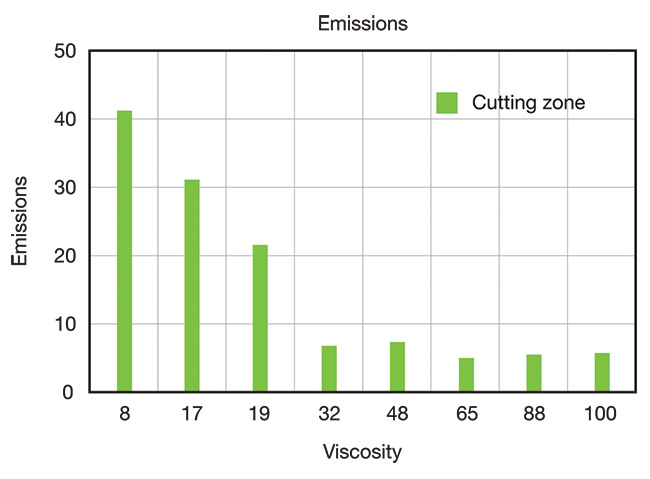

Generally, better wetting properties mean lower fluid viscosities. Unfortunately, lower fluid viscosities increase the tendency for the fluid to generate a mist. The table above shows measured emission levels at the cutting interface and at the extraction point for different viscosities on a drill. To help keep the emissions to a minimum, products with higher viscosities and flash points (> 150°C or 300°F) are recommended.

When selecting an MQL lubricant, one needs to balance its wetting properties with its emissions. This balance point will be different for open versus closed machines, and on closed machines with emission control devices versus those without. However, a high-quality, MQL-specific lubricant will work well with a minimal amount of misting.

Cost and other factors

A proper MQL system should use mere ounces of lubricant in a typical eight-hour shift. This “minimum quantity” required gives MQL its name and allows machinists to get impressive machining mileage from each lubricant purchase. When contrasted with traditional flood coolant consumption, MQL is clearly more economical. Because MQL is a total-loss lubrication method where only new, clean lubricant is used, there’s no need for circulation, filtration or treatment of fluid with biocides or fungicides. MQL’s neat application method delivers additional savings by reducing housekeeping and, at times, eliminating secondary parts cleaning.

Some synthetic ester-based MQL lubricants offer the additional benefit of being manufactured from renewable, plant-based materials with very little, if any, chemical additives. Their natural composition not only makes them a solid choice for the environment and makes them safe for workers.

For information on selecting a proper MQL applicator, proper setup and more, check out the free MQL Handbook.

Unist Inc.

Grand Rapids, Michigan

800/253-5462