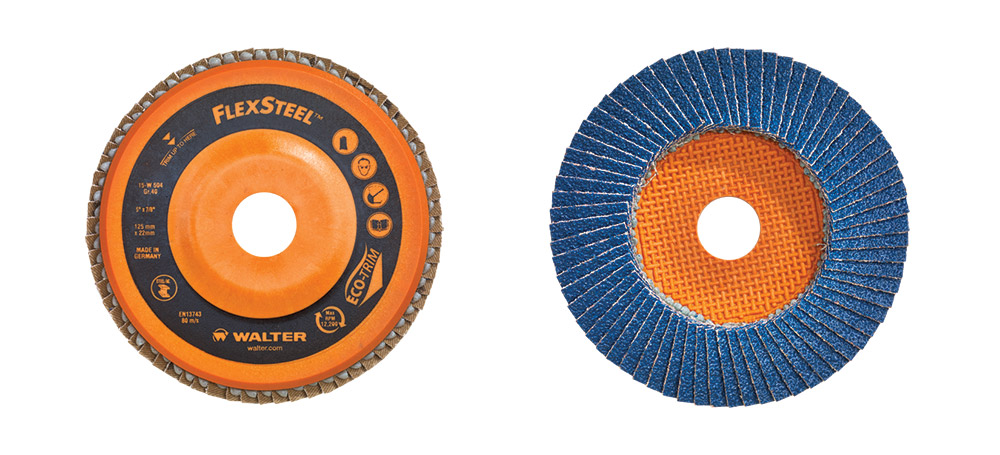

Above: Flexsteel enables metalworkers to get only the best out of their low-power grinder.

February 2017 - “My only goal is to stay focused on my craft and make sure my life is as sharp as it can be to attack any character that is given to me,” says actor Michael K. Williams, who famously portrayed Omar Little on HBO’s drama, “The Wire.”

Windsor, Connecticut-based Walter Surface Technologies, providers of abrasives, power tools, tooling, chemical solutions and environmental solutions for the metalworking industry, recently unveiled a product called Flexsteel.

Jonathan Douville, product manager at for Surfox, E-Weld and coated abrasives at Walter, designed the newly launched fla disc called Flexsteel. Douville describes it as “a flap disc that has been engineered to self-sharpen and stay sharp, even under low pressure.”

Douville proceeded to detail how Flexsteel distinguishes itself from competing products.

“You have to understand that the current Walter flap discs are designed to work with Walter grinders, which are quite powerful,” he says. “However, not every metalworking shop owns a Walter grinder. Flexsteel enables metalworkers to get only the best out of their low-power grinder.”

Flexsteel features an Eco-Trim backing made of wood fibers, which Douville claims makes the disc easy, safe and pleasant to trim. “It is manufactured under a patented process that makes sure the discs do not go in an oven to cure the glue. Dryness is the worst enemy of a coated abrasive. This is the reason we store all of our coated abrasives in a controlled humidity room.”

Flexsteel discs contain zirconia alumina grains that self-sharpen when facing low pressure, which means it continues to be effective and durable throughout the finishing process. Douville’s creation can also help metalworkers prevent interruptions and maximize output.

“Our product enables owners of low-power grinders to achieve an overall higher productivity by reducing labor costs and reducing abrasives costs,” says Douville. “Flexsteel lasts two to three times longer than competitive products. Plus, if a customer has a trimmable backing, our product will outperform any flap disc out there where premature wear of cloth is an issue.”

Flexsteel is especially useful for people who work in the construction industry or in an automotive or any other manufacturing plant that require parts grinding. “Flap discs are the fastest growing abrasive segment,” Douville asserts. “They are safe, can remove [material] like grinding wheels, leave better finishes, and offer a longer service life.”

Walter Surface Technologies

Windsor, Connecticut

860/298-1100