July/August 2017 - “Give me six hours to chop down a tree,” said President Abraham Lincoln, “and I will spend the first four sharpening the axe.”

Cibo Abrasives USA Inc. has attempted to sharpen the axe for many designers and manufacturers across the globe. A third-generation family-owned business, established in 1948, provides technical solutions for abrasive materials and products. In particular, the Cumming, Georgia-based company specializes in products used in the grinding, polishing and finishing of stainless steel, aluminum and other alloys that are difficult to machine. Cibo’s clients include makers of stainless steel handrails, architectural and ornamental iron work, tanks and vessels, commercial kitchen appliances and aerospace equipment.

Time Saving Kits are a solution for application problems that end users commonly encounter, says Adam Staley, Cibo’s business development manager. There are six kits each containing a separate solution. The kits consist of a diverse array of tools and abrasives to conduct tests and finish a job, alongside detailed instructions. Users should experience more comfort during grinding and be able to reduce abrasive steps, downtime, costs, noise and vibration.

Staley outlines what each specific solution is designed to accomplish.

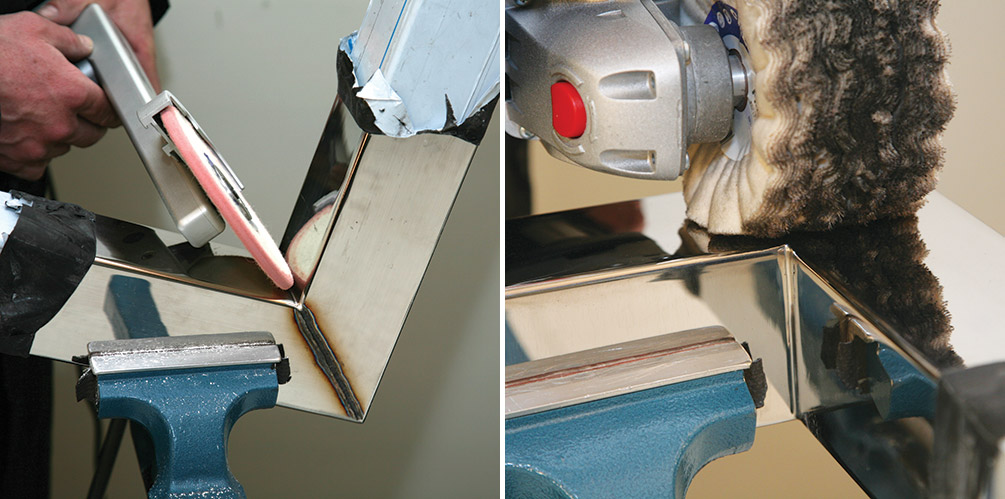

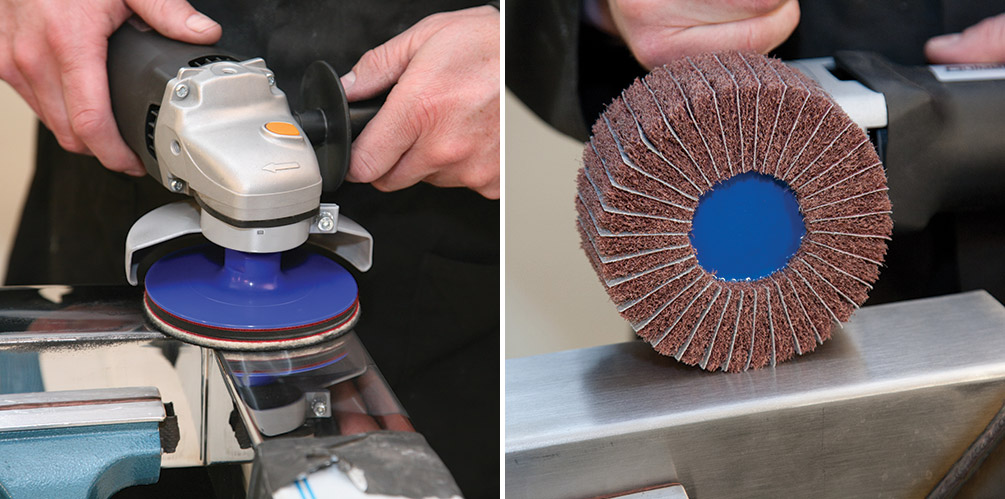

“The first kit helps with brush finish of mitres and outside box sections. The second is for brush finishing of inside box sections and tube joints. Third is for brush finishing outside tube joints. Fourth is for mirror polishing of mitres and outside box sections. The fifth kit helps with mirror polishing inside box sections and tube joints. Lastly, the sixth kit is for mirror polishing outside tube joints.”

Minimizing struggle

Staley says that, by analyzing manufacturing processes that consume stainless steel, Cibo researchers determined which primary setbacks end users faced in finishing their products. Subsequently, Cibo’s team released its solutions to minimize manufacturers’ struggles and differentiate its consumable from those offered by competitors.

“For every specific application,” says Staley, “we developed a Time Savings Kit.

The kits hold all the required abrasives, including accessories like backup pads and polishing compounds, to finish a perfect job.”

Each kit comes with a step-by-step instruction sheet that guides stainless steel fabricators through the entire process by giving hints and tips. Additionally, the company offers a link to a video demonstration that is akin to having Cibo’s application engineer performing a demonstration at a customer’s production site.

“The end user can define finishing processes according to market needs and reorder the products very easily,” says Staley. End users make “a very small initial investment by purchasing Time Saving Kits. We take a hands-on approach to ensure our consumer has all the tools, solutions and processes in a box. This is why we incorporate the phrase, ‘They don’t come with a book, they come with a box.’”

From raw materials to a completed product, Time Saving Kits can enhance a customer’s efficiency. Stainless steel, in particular, can be easily damaged by various fabricating techniques, which becomes a costly error. “We noticed that many metal fabricators try to avoid stainless projects for those reasons, although the market demand for stainless products is growing,” says Staley.

“Stainless steel transfers heat very poorly and virtually gets hot just by looking at it,” he jests. “The entire Cibo finishing concept is based on heat reduction by reducing operational speed and using three-dimensional abrasives. Essentially, this concept changes the entire approach. We try to teach our customer to work more slowly during the first, more aggressive steps to avoid damaging the material, so they can save time during the finishing steps.”

Multipurpose tools

To complement its Time Savings Kit, Cibo sells a range of variable speed, multipurpose power tools. The Time Savings Kit can be even more useful when used in conjunction with these tools. Altogether, Cibo’s kits are vital for welding shops.

“The Time Saving Kits’ concept, as a total solution, will remove any remaining doubts a metal fabricator might have to start working with stainless steel or improve processes,” says Staley.

Any welder “will feel more confident and comfortable working with this product. They will also learn that Cibo abrasives are forgiving, meaning that all finishing errors can be corrected at any time,” he says. “Cibo has ground away every reason not to get a perfect job done with stainless steel.”

Cibo Abrasives USA Inc.

Cumming, Georgia

704/770-1698