Displaying items by tag: abrasives

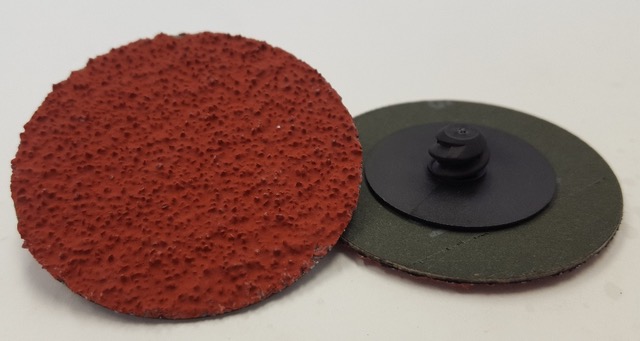

Ceramic Ultra-X discs

May 15, 2018 - The new Ceramic Ultra-X grain is manufactured in a new way that results in a much finer crystalline structure. Such a unique mineral fracture provides the abrasive product with a longer life, and more aggressive grains with an improved self-sharpening effect.

Significant performance advantages include a higher metal removal rate at faster cutting speeds with a lower grinding temperature and less friction. All of which correlate to shorter cycle times and less disc changes, resulting in reduced cost per part and an excellent cost/performance ratio.

In addition, the Ceramic Ultra-X line is top-sized. A top-sized product can positively impact the workpiece through a reduction in metal discoloration/oxidation, as well as minimal heat related stress cracks. It can also benefit the abrasive through reduced loading, glazing and dulling.

Gemtex Abrasives

Toronto, Canada

800/387-5100

www.gemtexabrasives.com

New generation of abrasives

Unitized material comes in various thicknesses, sizes and densities and allows you to finish materials in a simple and consistent manner. Unitized material differs from traditional abrasive materials because it combines aggressive action with an excellent finish. It is indispensible in finishing processes that use stainless steel.

Cibo

Haacht, Belgium

+32 (0) 16 61 85 85

www.cibo.be

An alternative to acid pickling

The F-Line discs from Cibo’s Rebel One line of unitized abrasives are an environmentally friendly, cost-effective and time-saving alternative to chemical pickling of stainless steel and nonferrous metals after welding. The F-Line discs also quickly and safely remove lacquers and coatings. The F-Line is 100 percent VOC compliant and solvent free.

Cibo Abrasives USA

Cumming, Georgia

704/770-1698

www.cibo-abrasives.com

Achieve better finishes on stainless, titanium

The CZT 1050 trimmable flap disc has a patented 5/8-11 quick-change hub. Its top size ceramic/zirconia alternate flap configuration provides cool cutting, high stock removal, long life and better finishes on stainless steel, titanium and all heat-treated steels. The discs are available in 4½ in. and 5 in. with grits from 36-120.

Gemtex Abrasives

Toronto, Canada

800/387-5100

www.gemtexabrasives.com

Full line of cotton fiber abrasive products

Rex-Cut Abrasives provides metalworkers with premium grinding, blending and deburring products including grinding wheels, unitized mounted points, premium flap discs, and specialized cut-off wheels. These products, as well as the new Type 1 Laser Braze Finishing Wheels, Versa-Cut Cut-Off Wheel and Quick Change Disc Max are featured in Rex-Cut’s new 2017/2018 catalog.

Rex-Cut Abrasives

Fall River, Massachusetts

800/225-8182

www.rexcut.com

Discs handle challenging materials

VSM’s quick-change discs are made from a high-performing ceramic grain (KSK+) supported by a resin fiber backing. Compared to other ceramic grains, KSK+ provides up to a 30 percent increase in stock removal, allowing these discs to excel on difficult-to-grind stainless and aerospace alloys.

VSM Abrasives Corp.

O’Fallon, Missouri

800/737-0176

www.vsmabrasives.com

Abrasive combines hardness and toughness

Cubic Boron Nitride abrasive, part of the Flex-Hone line, combines the highest hardness with excellent toughness to provide the optimum surface finish in materials like Monel, Inconel, Incoloy, Hasteloy, Invar and Rene. Flex-Honing is a low pressure, low temperature abrasive finishing process making it an ideal solution in these difficult to finish materials. The tool reduces the work-hardened layer produced by machining operations without imparting thermally induced distortion. The resulting surface is less prone to oxidation and stress induced cracking. Sizes from 4mm to 20mm are standard in three different mesh sizes.

Brush Research Manufacturing Co. Inc.

Los Angeles

323/261-2193

www.brushresearch.com

Ceramic discs are lightweight and aggressive

ADVANTAGE ceramic grinding discs are 100 percent more aggressive than a standard aluminum oxide grinding wheel and 70 percent lighter than a conventional grinding wheel. The state-of-the-art ceramic grain combined with the proprietary backing creates a disc with the toughness of a grinding wheel and the rapid material removal of a resin fiber disc. The ergonomic modified Type 29 shape provides greater disc contact on the work surface to improve metal removal speed. ADVANTAGE is available in both 4-1/2 in. and 5 in. discs sizes in 36 grit for fast stock removal, and 50 grit for a more refined surface finish.

Rex-Cut Abrasives

Fall River, Massachusetts

800/225-8182

www.rexcut.com

Flapbrushes provide consistency

Divine Brothers Co. flapbrushes can be mounted with any 5/8-in. by 11-in. shaft. These versatile brushes will make any job easier. Waterproof, the brushes feature a consistent finish and flexiblity. Satinmaster materials increase the true surface area by generating a micro-scratched surface. Satinmaster products are easily conformable to various shaped parts encountered in shops.

Divine Brothers Co.

Utica, New York

315/797-0470

www.divinebrothers.com

Wheels offer durability and better finishes

Gemtex expanded its non-woven product line with a “Premier” Ceramic Strip Away wheels. The wheels are made in North America with high quality standards to provide cool cutting surface removal with long life and a better finish on stainless steel, titanium and all heat-treated metals. The Premier range consists of type 1 wheels, type 27 wheels, type R quick-lock style and spindle-mounted wheels. Diameters range from 2 in. to 8 in.

Gemtex Abrasives

Toronto

800/387-5100

www.gemtexabrasives.com